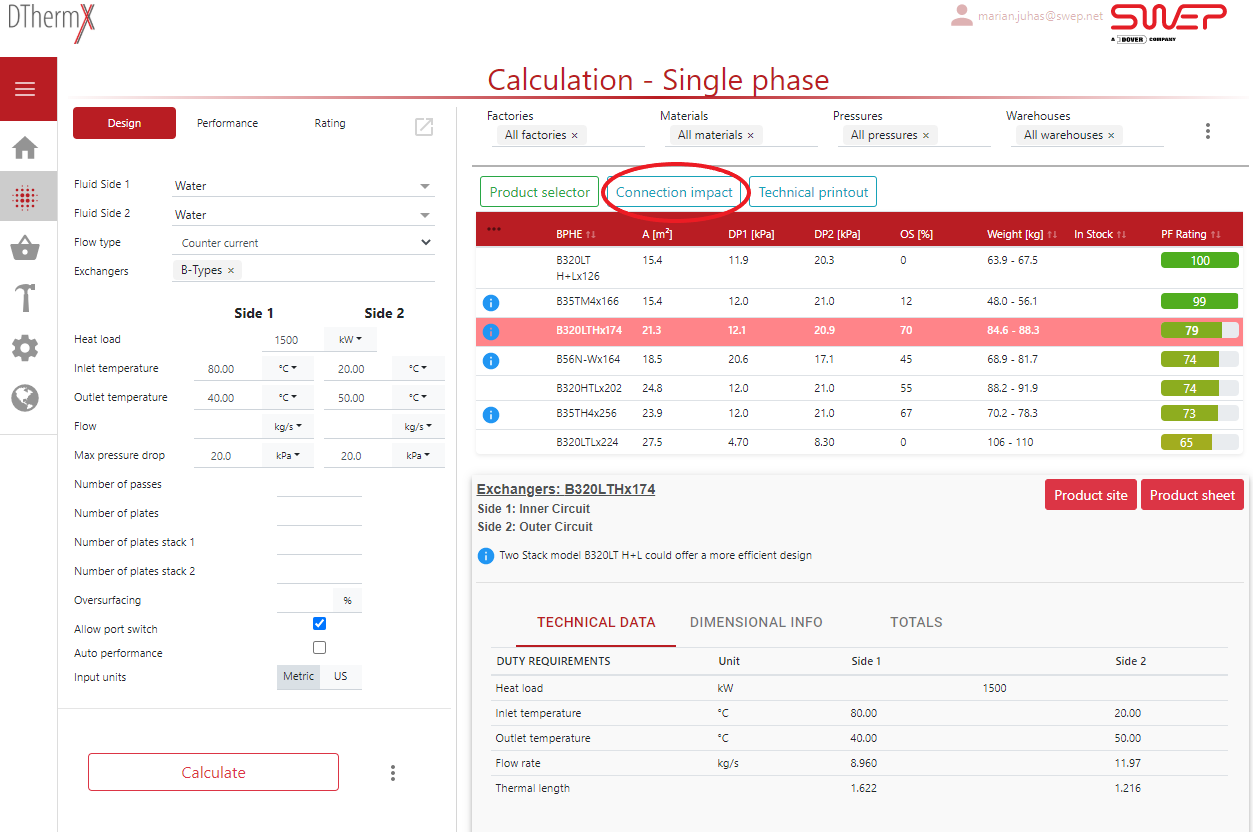

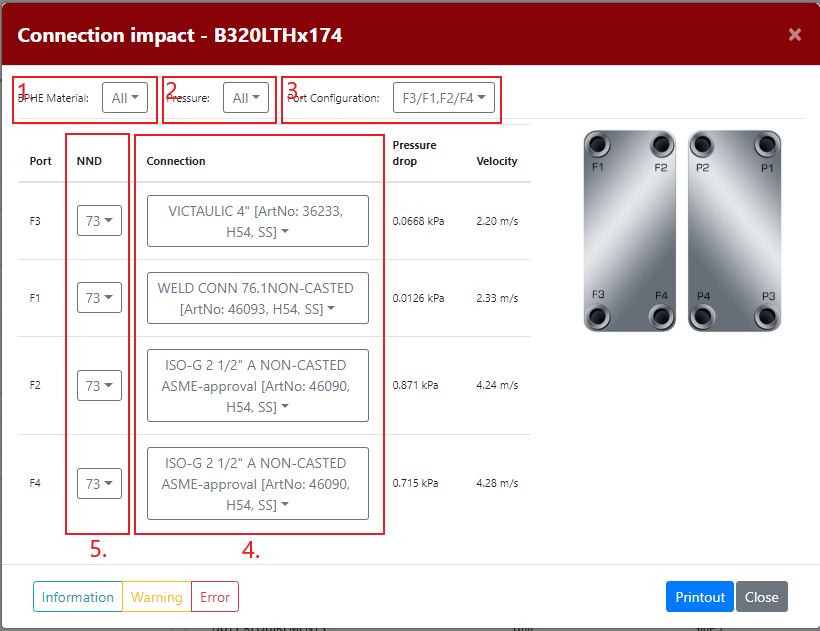

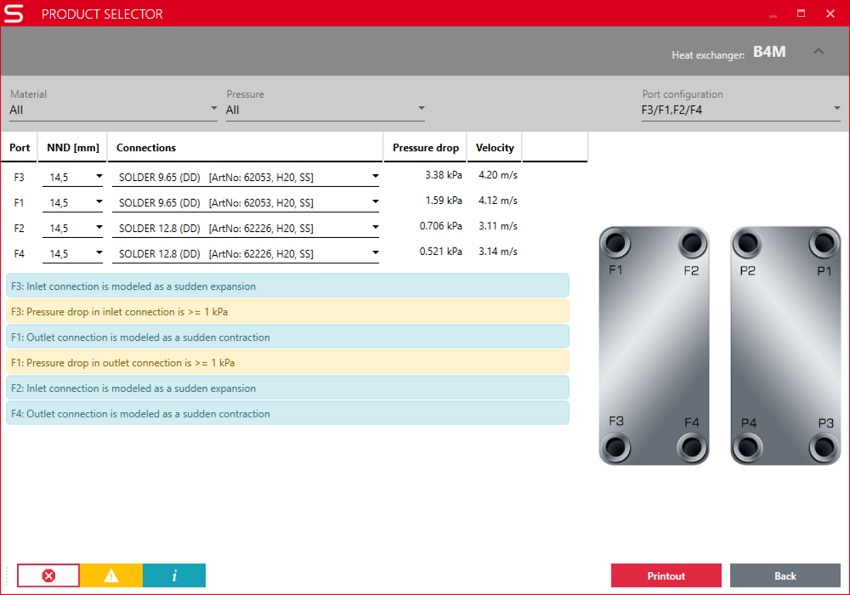

It will allow choosing connections available as art no.Connection impact provides fluid speed and pressure drop in the interface between BPHE and connection, incorporates these values to the BPHE total pressure drop. It also guides and warns on the correct connection selection.

Accessing connection impact tool and selecting connections

Once a user have calculated and selected a BPHE it is possible to click the connection impact icon in the tool bar as per Fig .1.

¶ Functionality

Connection impact tool consits of following parts:

- Connection material filter

- Pressure class filter

- Port configutation selector

- Available connections for each port

- Available Nozzle neck diameter (NND) for each port

Drop down menus 1 to 3 act as filters that will display only the connections for art no for the selected BPHE. If a connection is not shown, please make sure that connection material and pressure drop down menus are set to all, so that all available connections are shown. It's possible to increase the window size in order to see the article number if they aren't visible using the original size.

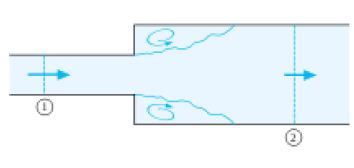

Pressure drop calculation

Pressure drop in the connection is calculated as a sudden expansion/contraction pressure drop calculation.

Printout feature

When clicking printout button, the user will obtain a document with all the BPHE data for the calculation case, same function as print button in SSP main interface. The difference is that the "pressure drop– total" now include the connection pressure drop.

¶ Recommendations

Velocity limits for single phase fluids

Connection velocity is limited due to pressure drop issues. When the pressure drop increases, the pump power increases for a given water flow.

The velocity limit in the connection is different from the velocity limit in the plates and ports. This velocity limit is considered in normal SSP calculations, where warnings are given on excessive velocity in ports and/or channels, which may cause erosion in the BPHE.

For liquids, velocity limit in ports and plates is set to 5,5 m/s

For gases, velocity limit in ports and plates is set to 100 m/s

For steam applications velocity in ports and plates is set as per graph in Fig .6.

Velocity limits for evaporators

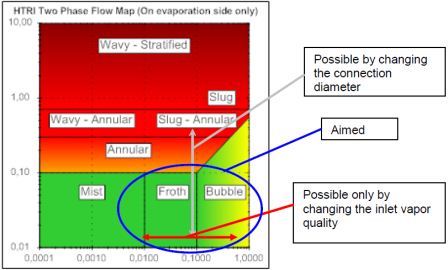

The size of the inlet connection should correspond to a velocity between 10 and 25 m/s in order to ensure a good distribution of the fluid, see "Flow patterns" below.

Connection outlet velocity should be higher than 5 m/s to avoid oil retention in the evaporator. It should be below 25 m/s to avoid maldistribution and instable evaporation.

Velocity limits for condensers

Condenser inlet velocity should be 5–25 m/sec to ensure good distribution and condenser performance. For condenser outlet the recommendation is 0.5–2 m/sec to ensure good condensate control.

Evaporator calculations

Fig .7. is representative for selections of connections for an evaporator. This and below is also valid for selections for dual evaporators and cascade units. Once the connection is selected, the tool provides the user with pressure drop and velocity values in the connection. It also provides with some messages in the bottom part.

There are three types of messages:

- Error messages: critical message that indicate an improper selection of a connection

- Warning messages: important message that indicate information the user should be aware of

- Information: mentions interesting information about the calculation

Fig. 7: Connection impact tool with Two phase flow pattern map for evaporators

Flow patterns

The homogeneous flow patterns (Bubble and Froth) flow are desired flow patterns at the inlet of the evaporator. Annular, annular-slug or even wavy-stratified is not recommended since this increase the risk of maldistribution. Bubble and froth can be obtained by choosing the correct inlet connection.

The flow pattern that provides the best distribution is the mist fluid regime. Mist regime cannot be achieved in BPHEs. The second best distribution is achieved in the froth or bubble flow regime, which can be obtained in BPHEs according to above.

By increasing the dimension of the connection, we move vertically upwards in the graph. By increasing the X inlet value, we move horizontally to the left in the graph, (see Fig .9).

Inlet and outlet connection recommendations for evaporators

In addition to velocity and flow pattern the connection and pipes should be selected to fit port size. This is important to avoid extra pressure drop (if the diameter changes several times) and to avoid regions where liquid refrigerant can be stagnant.